Tests of Arbuckle Majolica glaze on two different low fire clay bodies, Standard 105 White (top) and Standard 103 Red (bottom). The majolica glaze was mixed to a specific gravity of 1.45. At left shows 2 dips, a 3 second dip over the whole tile and a second 3 second dip angled at the top left. The middle tiles show oxide washes over a 3 second dip of majolica. The tiles at right show oxide washes over two dips of glazes (3 seconds each dip.)

Detail of Arbuckle Majolica over Standard 105 low fire white clay body, fired to cone 04.

This post shares tests of the low fire white glaze, Arbuckle Majolica, along with oxide washes mixed to the specifications found in Linda Arbuckle’s comprehensive Majolica Handout.

Detail of Arbuckle Majolica over Standard 103 low fire red clay body, fired to cone 04.

I have been experimenting with oxide washes at midrange temperatures and wanted to see if I could get similar at a lower temperature. I have also been inspired by numerous artists making great work with low fire clay and glaze, along with the recently published Low-Fire Glazes for Potters and Sculptors by Ben Carter. (shop book at Amazon) This Majolica recipe is found on page 159 of that book, although it is readily available online in many places.

Arbuckle Majolica, low fire white glaze

| Ingredient | Percentage | 1000g batch |

|---|---|---|

| Frit 3124 | 66 | 660g |

| Minspar 200 | 17 | 170g |

| Tile #6 Kaolin | 11 | 110g |

| Nepheline Syenite | 6 | 60g |

| Tin | 4 | 40g |

| Zirconium | 9 | 90g |

| Bentonite | 2 | 20g |

Oxide Wash Recipes

The 8 washes made for these tests.

1 part colorant

1 part Frit 3124

1 part Bentonite

Recipe for: Copper Carbonate, Cobalt Carbonate, and Synthetic Red Iron Oxide

For these tests, 20 grams of each were mixed.

The 60 grams of dry materials were then mixed with 250 grams of water.

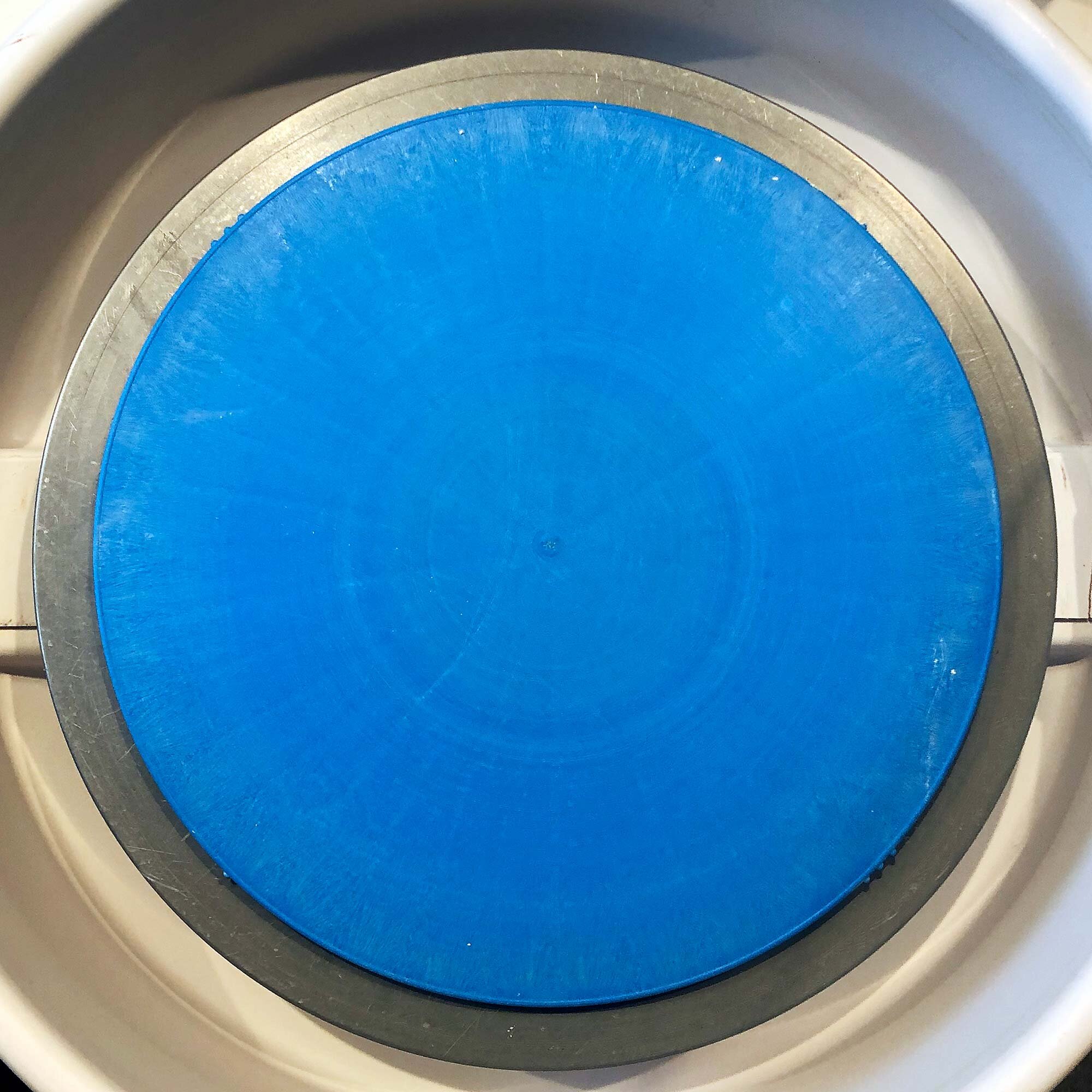

Cobalt Carbonate wash in a 16 ounce deli container.

1 part colorant

1 part Frit 3110

1 part Bentonite

Manganese Oxide was used in this test

20 grams of each were used in these tests.

The 60 grams of dry materials were then mixed with 275 grams of water.

1 part colorant

3 parts Frit 3124

1 part Bentonite

Chrome Oxide, Light Rutile, Titanium Dioxide, and Mason Stain 6600 Best Black were used in these tests.

20 grams of colorant, 60 grams of frit, and 20 grams of bentonite were used in these tests

The 100 grams of dry materials were then mixed with 300 grams of water.

Note on water:

These were mixed until they seemed usable, based on my experience. You may want a thicker or thinner mix.

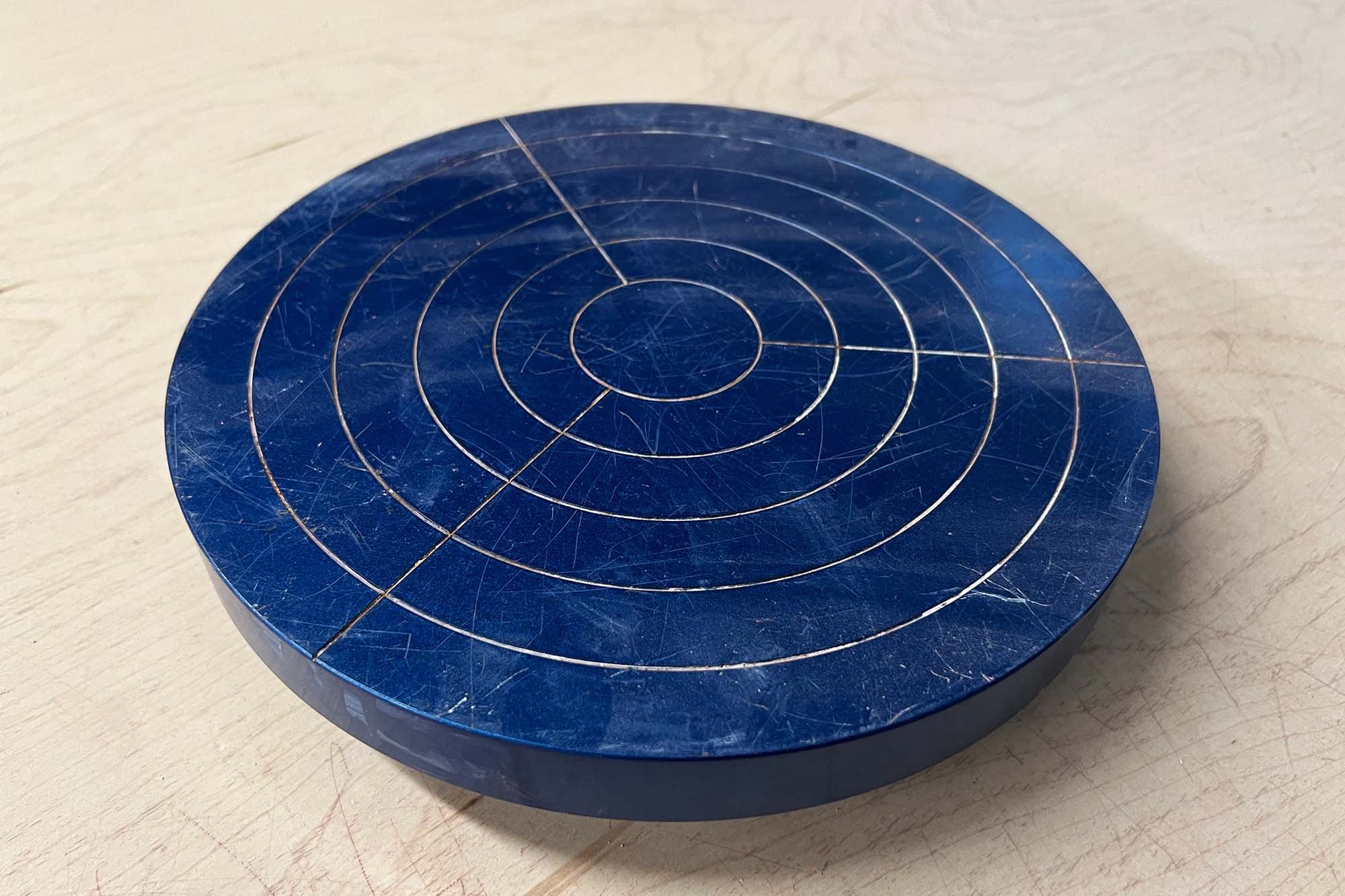

Majolica glaze results:

The glaze is an easy to use, durable white glaze that gave me nice results on test tiles. I plan to add it to my studio. As seen on the red clay test tile, a thin coat allows some body color to come through, and a double coat is a more solid white while still seeing some body color where the glaze breaks over texture.

Oxide Wash results:

From previous work at midrange and high fire, I am used to mixing oxides just with water for high fire, or with something that helps the oxide melt at midrange, such as a frit. The recipe from the Arbuckle handout (listed above) includes mostly Frit 3124 along with bentonite to help the oxide stay in suspension and resist smudging after it has dried.

I can attest that the bentonite did result in a brushstroke that resists smudging, but I found the overall mix to be somewhat gelatinous. This resulted in an application that started out thick but quickly became thin throughout the brushstroke. Sometimes I was depositing too much oxide, and others were quite thin. I would like to test again with maybe half the percentage of bentonite, so for example a recipe of 1 part colorant, 1 part frit, and a 1/2 part bentonite.

I would also note that the oxides with the 3 parts frit generally melted better and didn’t have surface breakups. Another point of testing would be to increase the frit percentage for all the oxides.

You can see in test tiles that the oxide effect also varied based on the thickness of glaze. Obviously, I will have to do more testing to get the results that please me, but sharing these results here as they may be a starting point for others to develop what works for them.

Storage: 60 to 100 grams of material with water fit a 16 ounce deli container. This is a LOT of oxide wash for an individual studio. You may want to mix smaller amounts.

The oxide washes at Cone 04 over Arbuckle Majolica (top) and G1619Q / Quigley Clear at bottom

Same recipes over low fire clear: These were also tested over G1619Q / Quigley Clear glaze, and had nice results. Not majolica, but the oxides melted more on the clear and had nice results.

Low fire versus mid range: the same recipes were tested over Arbuckle Majolica fired to Cone 04 at left (both a single and double dip) and at right, over the VC Soft Satin 1 Glossy White fired to cone 6.

Same recipes at cone 6: These recipes were also painted on VC Soft Satin 1 Glossy White modified with Frit 3134 and the results were ok, if a bit muted. They might need to be mixed thicker or have a higher percentage of colorant if used at mid-range temperatures.

Individual notes

Light Rutile Oxide Wash: Good straw yellow when applied thickly. Brushstrokes developed when applied thinly. Might need to paint designs twice or use less water.

Copper Carbonate Wash: Oxidized copper green as expected. Where applied very thick, had breakups in final glazed results

Cobalt Carbonate Wash: Worked as expected over clear glaze. Where applied thickly, broke up. Might need more frit, such as a 1 part colorant to 2 parts frit.

Synthetic Red Iron Oxide Wash: Was most iron red on majolica glaze over red clay. Did not benefit from a thicker application of majolica glaze underneath.

Chrome Oxide Wash: Very refractory, as expected. Did melt ok over a thinner glaze application. Did not benefit from thicker majolica glaze. Melted quite well over clear glaze.

Manganese Oxide Wash: Plum to brown with the Frit 3110 mix. Had issues breaking up with both thick and thin application. May need more frit in the mix.

Mason Stain Best Black 6600: Ok black, did not benefit from thicker application of glaze. Already has a high percentage of frit, might need more.

Titanium Dioxide Wash: I knew this would be hard to see on a white glaze, but there was some contrast there. Especially interesting over the clear glaze over red clay, where it’s a pale yellowish white.

Conclusion

The Arbuckle Majolica is a great low fire white. I had mixed results with the oxide washes, but have a direction to go for further testing to get the washes locked in for the results I am looking for. I generally don’t want the brushstroke / washed out look, but that may work for you.

You may also enjoy: